The project company CJSC «String technologies» is known for unique developments, innovative solutions, unusual approaches and bold ideas.

One of the main components of our transport complexes is an electric motor, which is a part of the SkyWay motor-wheels.

There are DC and AC motors, and the latter in their turn, are divided into asynchronous and synchronous ones. Their main difference is in the design of the rotor: in a synchronous motor, it is a permanent or electric magnet, while in an asynchronous motor – the poles on the rotor are induced by the magnetic field of the stator.

In SkyWay vehicles, for example, there is used a synchronous traction electric motor, built into the wheel or a motor wheel.

The transport module equipped with electric motor- wheels has a number of advantages:

- Lack of complex and heavy transmission mechanisms between the engine and the wheel, additional elements such as a clutch, transmission, drive shafts, differentials, operating «as one unit set» with an internal combustion engine.

- Better dynamics, development of maximum torque at the lowest rpm.

- A simple replacement of software algorithms.

- A safer device due to the lack of combustible substances.

- And, of course, environmental friendliness.

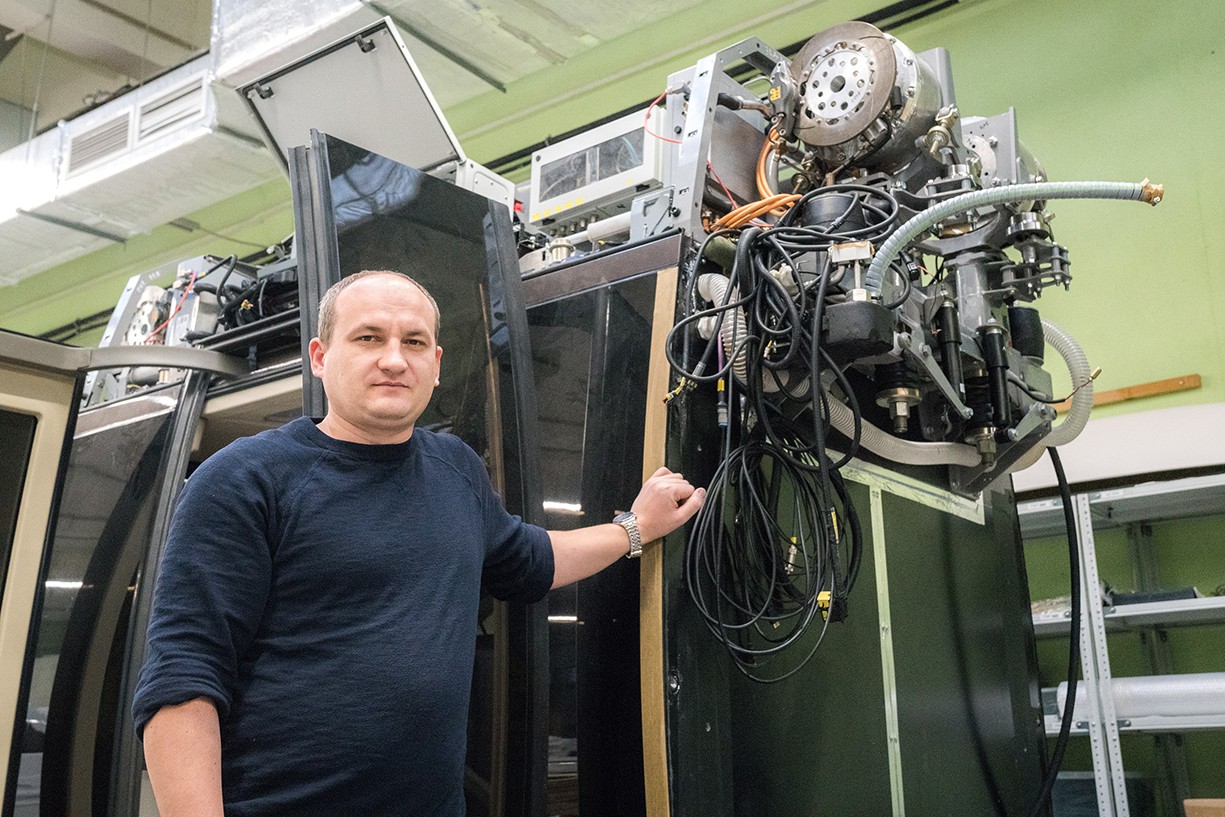

In order to find out more details, we talked to the Head of the Design Office of the Pilot Production of Electric Drives,Ilya Zhagalskiy.

-Good afternoon! Could you tell us, what your office is engaged in?

-Good afternoon! We are engaged in the development and production of electronics, power and converter equipment, as well as electric motors and energy storage devices.

- Could you please clarify? Initially it was the Design Office«Electric Drive& raquo;, and then it was renamed to Design Bureau with the Pilot Production of Electric Drives, is that so?

- Not quite. In fact, a new Management office has been created. Initially, we belonged to the Management of the Rolling Stock. And then, for greater efficiency, by the decision of the General Designer Anatoliy Yunitskiy, we were set apart as a separate Management with a new name of Design Bureau with Pilot Production of Electric Drives.

- What kind of specialists work in your office?

-Design engineers, electricians, electrical fitters, mechanical assembly fitters.

- What do you do as Head of the Bureau?

I manage the Bureau and deal with the development of the electronics, creation of software.

- What vehicles use the motor-wheel?

- Electric cars, electric bicycles, mining dump trucks, hoverboards.

- Why has this type of engine been chosen in the development of the string transport?

- It happened, as it has the best specific characteristics, namely, torque per unit mass. That is, with smaller dimensions and weight, we get more torque. This motor has also a more flexible control in a wide range of speeds. Its efficiency is higher than that of other types of engines.

- Why was it decided to design our own motor wheels instead of using the available options on the market?

- The market does not always have suitable options for characteristics and parameters. And if you order a third-party individual development for our projects, it turns out to be long and quite expensive.

- In this case, our electric motors have a distinct advantage – they are designed individually for each vehicle. Can you name any other advantages?

- In comparison with the options available on the market, with smaller weight and size indicators, we can get more power. We have achieved this due to calculations and experiments.

- Are you planning to start mass production?

- Yes, we now have pilot production for the development and creation of engines for our vehicles, but we plan to launch a serial production, as our electric motors are very competitive in terms of price-quality.

- How many types of motor-wheels have been created by your office? Does each vehicle has its own type of engine?

- Unicar, monorail and double-rail unibuses – have the same engine. The first two use 4 motor-wheels, and the last one – has 12. Uniwind, has the motor of smaller dimensions and power. Unicont and high-speed unibus, on the contrary, have more powerful and bigger motor-wheels. That is, at the moment, there have been developed and manufactured 5 types of engines.

- How powerful are they?

– 10, 20, 28, 35, 60 kilowatt.

- The other design offices are in the office building, and you are in production one – why is that so?

- There are more possibilities for us here. We need to work with a test bench, need a laboratory, assembly areas, equipment, three-phase voltage – we can't have all these in the office.

- Could you tell us about the Bureau, about the team?

- We have a good team, which already consists of 26 people. We are growing, developing: 70% of the employees are our engineering staff, which are engaged in the development and maintenance of products at the production. The rest are engaged in the assembly and testing of the prototypes. We do everything ourselves from the idea to a physical sample.

You can also watch the video about the motor-wheel, was filmed earlier.